Chorizo number one

This first attempt went as follows:

Ingredients:

2,0 kg Lean

pork (ground 3mm plate)

400g Back

fat (ground 3mm plate)

67g salt (3%

accounting for Prague Powder) – Himalayan rock salt slightly coarse

9g Prague

powder

5g Glucose

powder

5g light

brown sugar

50g Smoked Paprika

(Cape Herb Company)

5g Oregano

5g garlic

powder

14.4g

cracked black pepper

0.6g Bactoferm TD-66CHR Hansen Mold-600 sprayed on after stuffing, linking and ready to hang (Optional)

Method:

The meat and fat must be kept close to frozen while grinding and mixing. To maintain this, put your mincing attachment in the freezer before use and keep returning your ground product to the freezer to chill. After grinding, mix all the ingredients thoroughly kneading them together then

,

stuff into Hog casings and tie them into loops. There are a few different tying methods. I used the "Bubble knot method"

I mixed the Bactoferm TD-66 powder with the spice mix to help blend this through the meat. You can also mix in with distilled water then blend through. Rather mix more than you need as it cant do any harm. I have also read you should use a minimum of a quarter packet (i.e. enough for 25kg meat) to guarantee you have enough bacteria blended through the meat.

If going with the mold, when ready to hang spray with the MOLD-600. This was made up of 1 gram of CHR Hansen MOLD-600 in a quarter cup of luke warm distilled water left to stand for a couple of hours then diluted into a cup of distilled water. Put this in a clean spray bottle to apply. The benefit of the mold is it takes hold quickly and prevents bad mold from getting the opportunity to set in. any mold that is fluffy or a colour other than white is BAD; wipe it off with a cloth and vinegar.

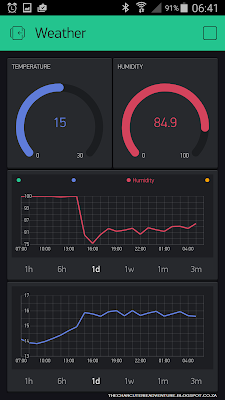

Hang your links in your curing

chamber set up as a fermenting chamber (temp set-point 20°C, controlling

between 18 and 21°C) and (Humidity set-point 87%RH to target control between 85% and 90% relative humidity)

Leave it there for 72 hours at this setting then dry at 12 to 16°C 80 to 85% humidity until you get 35% weight loss. This is expected to be a couple of months. To monitor this I labelled each Chorizo then weighed and logged their starting weight.

A daily PH check confirmed an acidic environment. PH should be around 5 after 30 hours. you need an acidic environment to prevent bad bacteria from taking hold and growing. These will spoil your meat.

PH test method: When you hang your meat, keep some separate for testing. This can be left in a bowl or just a hanging open link. Keep this inside your fermentation chamber with your Chorizo. I kept a short stuffed casing open one end and just squeeze out a meat sample as required. Mix this sample into a clean ramekin with distilled water. To test PH I am using a universal indicator paper (form of Litmus paper). The paper I have is to measure a range 0 to 14. If buying, rather go for a smaller range like 4,5 to 7. This will be much easier to read. Dip the paper in the sample and compare the colour to the scale supplied with the paper.

Side note: Keep your environment and equipment extremely clean. During fermentation and curing you are creating an optimal environment for bacterial growth. do your best to keep the bad bugs out. When mixing the meat by hand, wear disposable latex type gloves.

The above mix gave a yield of 9 links averaging 275g each from this batch:

|

| Chorizo entering the fermentation chamber |

|

| Chorizo marked. Salami in for company |

The Mold started to show noticeable cover within 24 hours and excellent coverage a few days later.

|

| Mold 48 hours |

|

| Mold 1 week |

Equipment used:

01 August 2016 - Update

21 days after hanging and diligently controlling the temperature and humidity (refer to the temperature and humidity control problems found and solved here)

I cut open and sampled my first Chorizo last night.

First things first. Here is the drying profile for my 9 Chorizo's:

Here is how it looks after wiping mold off with vinegar rinsing, drying and slicing:

First impressions:

Flavour: Superb. I made this batch without the hot side of the spices. A little Cayenne or hot paprika would add nicely to this. The flavour however is fantastic.

Texture: A little difficult to tell. I believe it needs to dry a bit more. I have re-hung this, will sample again at 50% moisture loss. Currently the texture is a little too close to a "raw meat" texture - too close for my wife to enjoy. Update 6 weeks later effectively at the end - I say the end as I seem to have reached a drying equilibrium for the humidity and temp. Texture hasn't improved. I'm not impressed. I am now wondering if the paprika etc has an influence on this. I say this as I tried my Salami made at the same time yesterday and this does not have the texture problem.

Size: I would like to get hold of a larger casing for this. something in between the hog casings I used and the small salami size casings. I haven't managed to source anything yet.

General: The Chorizo is drying nice and evenly. There are no indications of "case hardening" around the outside. The residual mold has no negative flavour effect. The hog casing peels off easily although a little meat sticks to it. This would also improve with some more drying time. The Chorizo I have had travelling in Spain is definitely dryer than this. They also don't appear to have the shrinkage and wrinkling I find. I need to figure that out, maybe stuff the casings fuller. The wrinkling of the casing makes wiping off the mold challenging.